Boeing: 1, 2, 3 Strikes, You're Out

Image Source: Unsplash

"But wait," some will say. "(1) There are only two giant commercial aircraft manufacturers in the world. (2) Air travel will only increase. (3) Ergo, Boeing must benefit."

There are indeed only two mega aircraft manufacturers that can handle current anticipated air travel needs in quantity, Airbus (OTCPK: EADSY) and Boeing (BA). That does not mean, however, that they will share equally in new orders. Based upon safety issues, manufacturing costs, labor strife, and a host of other issues, one may easily prove to be the better stock buy - *if * your universe of buys is restricted to one of the two giants in this industry.

It is also true that, even if both EADSY and BA are the recipients of equivalent-value airline orders, that does not mean that they will each make equivalent profits from those orders. The better question is: can Boeing make a profit in their commercial and defense work that will lead to sustainable profits? The most important question to answer is, can Boeing build aircraft that do not require costly repairs for which Boeing is contractually liable?

Why I am not buying Boeing even at these lower prices:

- Boeing management is no more transparent with the facts than it was five years ago or three years ago.

- Boeing management's first impulse is to say they want to cooperate fully with any investigation - while they circle the wagons.

- Boeing's push to get the product out the door means its quality control has not improved enough since the previous and recent disasters.

- Boeing has to spend billions of dollars every year for its cost overruns and rushed-to-market products on the defense side of the business.

- These problems result in lessened returns for investors.

- There are more transparent, better-led, more profitable companies available for purchase in numerous other industries.

It pains me to say the above. Boeing was once a shining example of American "can-do" manufacturing brilliance. They still have a gifted engineering team and, if they treat them right, a marvelous corps of workers who would make William Boeing proud -- if only the company would let the ability and honesty of its employees' hard work determine its future.

A short history of great manufacturing and smart financing:

Boeing stepped up to the plate in World War II for the Allied cause. They were renowned for quality first and speed of production a close second. The B-17 Flying Fortress and the B-29 Superfortress were among the most renowned bombers of the Second World War. Boeing immediately followed with the B-47 Stratojet, a bomber that was commissioned in 1947. A good friend and superb Air Force pilot always told me of the great pride he took in flying this aircraft in the early years of the Cold War.

Boeing was the first to build a serious and financially successful commercial jet airplane; the 707 inaugurated the age of jet commercial aviation. That airplane changed the world. Back then, Boeing was smart enough to sell commercial airlines what was "pretty much" the same aircraft as the government-funded (always read "taxpayer-funded!") Air Force KC-135 tanker.

Both the Boeing KC-135 aerial refueling tanker and the Boeing 707 commercial flight airplane were developed from the Boeing 367-80 prototype, also called the Dash-80. (The 135 has a narrower fuselage and is shorter than the 707, but once Boeing had the contract for the one, the other came rather more easily.)

Below is an early version of the 135, refueling a B-52 in flight. The body of the 135 is narrower because it does not need room for seats, aisles, galleys and such. It is a workhorse, not a showhorse.

KC-135 refueling B-52 (US Government / Public Domain)

707 Early Test Flight (space.com)

And here is the 707 in its first test flight in 1957.

The 135 entered service with the USAF in 1957. Not coincidentally, the first 707 test flight occurred in the same year. The 135's only competitor until recently was the McDonnell Douglas KC-10 which did not enter the Air Force inventory until its first flight in 1981.

McDonnell Douglas took a slightly different route. In 1971, McDonnell Douglas introduced the DC-10 to the commercial aviation world. 10 years later, they delivered the first KC-10 to the Air Force. The KC-10 retained an 88% commonality with the DC-10.

Today, the KC-135 is supposed to be partially replaced by the Boeing KC-46 Pegasus. That part of my analysis is outlined in Strike Two, below. But first…

Strike One

I wrote two articles about Boeing for Seeking Alpha subscribers in 2020, during the 737 MAX 8 fiasco. That "MAX" was the fourth generation of the narrow-body Boeing 737, an airliner Boeing had years and years of experience building. It was not a new airplane but an iterative change, making this an even bigger black eye for Boeing's manufacturing and safety superiority claims.

So much has been written about the safety and rush to production issues since then that I will only note a few key points I discussed in these previous analyses here on SA:

- Boeing and Airbus own a duopoly on commercial aviation. The barriers to entry are insurmountable for a new competitor unless it is funded by a sovereign government -- which could happen.

- It doesn't matter if you have a trillion-dollar backlog if you are selling at significantly lower margins - or a loss. Never forget the old saw about the guy who defends his results by saying "We're losing money on every order but we're making up for it in volume."

- The backlog of orders for both BA and EADSY extends over many years. If an airline wants to switch manufacturers now, the queue is so long that, by switching, it will only wait even longer to see those aircraft.

- In securing an order for 250 KC-135 tankers from the US Air Force in 1955, the plant itself, the research, the tooling, the wind testing, the flight testing, etc. (paid for by the American public via DoD) laid the foundation upon which Boeing designed and built its first commercial jet aircraft - the 707.

- The problems with the 737 MAX 8 are less engineering problems than they are a decision to rush a product to market when many of the company's own engineers warned against it.

- Continuing problems, seemingly every month: The engine-control wiring in the 737 MAX 8, like most aircraft, is supposed to have a metallic shield, sort of like an airborne lightning rod, that protects the wiring against damage from a lightning strike. Such a strike could result in a power loss to both engines in mid-flight. Do you want to be halfway across the Pacific when lightning strikes that one?

- The FAA estimated it should only take 12 hours of work for mechanics to check and repair the problems on each plane, so there will be apologists aplenty saying it's no big deal. If it's no big deal, why didn't the company spend those 12 hours before trying to sell the aircraft as safe and ready to fly?

- Boeing's own engineers warned management that you don't just sling a heavier engine on an airframe, then move the weight forward to deal with the weight and balance issues -- then insist upon a software solution for the ensuing erratic flight characteristics.

- All of these issues combine to mean that investors in Boeing are getting a raw deal. Investors are paying for Boeing management's failures in lower dividends and a lower share price.

All of the points I discussed then are hopefully common knowledge by now, including Boeing management's stonewalling of the issue. In both fatal civilian crashes that caused the FAA to ground 737 MAX 8 aircraft from flying, Boeing executives defended the company's design and manufacturing process in courtrooms, news conferences, and the court of public opinion.

The most egregious response was Boeing management's continued insistence that there were no problems with the hastily introduced MCAS system, suggesting that the pilots on both flights could have prevented the accidents if they had followed Boeing protocols. Too bad the deceased pilots of the Lion Air 737 Max 8, along with 188 others, and the deceased pilots of the 737 Max 8 crash in Ethiopia, along with 157 others, did not have the opportunity to disagree.

In my experience, there is never just one cockroach in the kitchen.

Strike Two

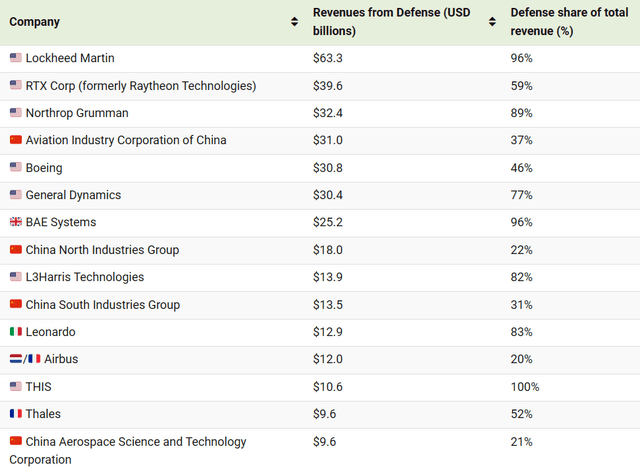

Most investors who own Boeing are drawn to the commercial side of the company and its duopoly on commercial aircraft. But in fact, 46% -- almost half! -- of BA's revenue comes from the US Department of Defense. When I wrote Boeing Vs. Raytheon: Which One Has The Right Stuff? Boeing was the 2nd-largest US military contractor, with ongoing contracts for Apache and Apache Longbow rotary wing aircraft, F/A-18 Super Hornet fighter jets, Air Force One and its twin, and many others.

In just four years, Boeing has slipped to #4 in the US and #5 worldwide - behind the Aviation Industry Corporation of China.

Visual Capitalist October 2023

How could this happen? After all, military Materiel Acquisition Project Managers will almost always choose the safest career path by going with the tried and true contractors that can fulfill the stated mission requirements.

Promotions in this field do not come readily to the manager who advises buying a Peel P50, a Yugo or a Trabant when he could have had a steady, dependable Ford or Chevy for the same price. (No Corvettes or XKEs, either; we are all about time to market, ramp-up capability, and access to parts here...)

In recent years, Boeing employees from Renton, Washington, to Charleston, South Carolina, have claimed there is a marketing and profits rule that always trumps an engineering and safety culture at the highest levels of corporate Boeing. This seems to have infected the military side of Boeing as well.

Enter the Pegasus

Let's look at Boeing's embarrassing sub-par performance in delivering the newest-generation aerial refueling tanker to the Air Force, dubbed the KC-46 Pegasus.

This nation cannot go to war without aerial refueling. Jet fighters, AWACs, bombers, transport, it doesn't matter - all of them are thirsty, and with the United States' foreign basing rights more in question than ever, the country desperately needs this airplane to perform as advertised.

I would like to see this aircraft delivered on time and within budget, but that train left the station long ago. It is already years behind schedule, and it looks like years more before it will be safe enough to enter into service and deploy to combat zones.

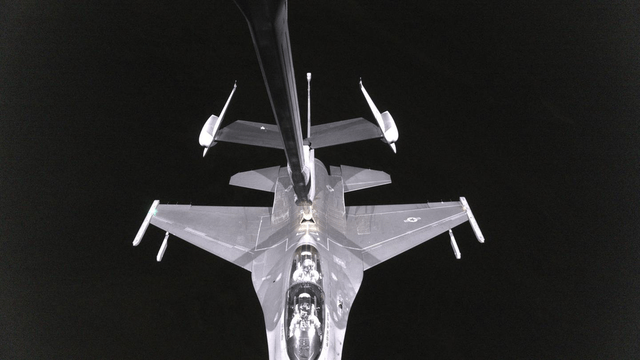

One of the problems I documented in previous analyses on SA included a major malfunction with the overly complex software inside the Remote Vision System. The RVS permits the in-flight boom operator to view the refueling system below the tanker without visual recognition.

Having personally performed this feat - poorly, but, hey! it was my first and only attempt - with a far less high-tech boom on a KC-10, I can assure you that both the fuel delivery aircraft and the customer should have eyes on the boom.

(In my case, the pilot of the F-16 was quite patient. He was relieved, however, when I handed the controls back to the Airman First Class who had done this a couple thousand times. I waved, the pilot saluted and, bam! just like that he was nowhere to be seen.)

The KC-46 also had and still has problems, not only with this high-tech "vision system," but also with how the boom connects and disconnects from specific aircraft, like F-16s and A-10s. In short, it was way too stiff and needed to be redesigned to be more flexible. Pilots of these lighter fuel-receiving aircraft reported they needed to use too much power to move the boom forward and to disconnect. This could lead to severe damage to the boom or the aircraft. If the former, there goes the gas station and there goes air supremacy.

A KC-46 Pegasus refuels an F-16 at night, as seen through the updated version of the Remote Vision System, or RVS 2.0. (Boeing)

I noted that KC-46 deliveries had also been halted or delayed many times as a result of the Air Force maintainers discovering FOD -- "Foreign Object Debris" -- like soda cans, trash, candy wrappers, tools, nuts and bolts, and other miscellaneous items - scattered inside the aircraft and possibly within the wiring. That may not be a problem in your car but in an aircraft, loose objects can cause serious damage. Who the heck at Boeing is doing Quality Control before delivering these aircraft? Or is this how disgruntled employees vent their frustration? And if so, why are they frustrated?

Part of the problem is that the KC-46 is basically derived from the Boeing 767, with the company either cutting corners or borrowing from known technology. 80% of the 15.8 million lines of code is supposed to come from existing software. Yet software problems determined to be "urgent" or "high-priority" continue to plague the Pegasus.

The unsung but brilliant Air Force Loadmasters take pride in ensuring the safety of all aboard. While the primary mission of the KC-46 is aerial refueling, it is a multi-mission aircraft. It can also carry cargo and passengers, transport troops, or be used as an airborne aeromedical evacuation center.

It took just one delivery of a Pegasus for USAF loadmasters to discover that one of the lowest-tech pieces of the aircraft, the mechanical cargo locks secured with webbing to the bottom of the deck, came unlocked all by themselves. Can you imagine a bay partly filled with non-ambulatory medical patients suddenly seeing a loose piece of artillery or Stryker coming in their direction? Or the weight and balance issues that the pilots would be struggling to control? This one was fixed on the affected aircraft, but the design flaw that allowed it had to be integrated into a retrofit for the entire fleet.

Of course, this was four years ago so, by now, it must all be resolved, right?

It is not. Having spent some of the best times of my life in the US Army and US Air Force, I still take an interest in such things and still have my lifetime subscription to Defense News. In fact, I was prompted to write this updated analysis partly because of the cover article this month, "How Boeing Won a US Air Force Deal and Lost $7 Billion." (Also reprinted in Air Force Times.)

The article begins with nearly the same words I wrote four years ago, but the real thrust of the article is that Boeing submitted low-ball bids on a fixed contract that other competitors refused to even bid on. That should have been a harbinger of problems in itself. Here are a couple of quotes from this most timely article:

…For years, the tanker, designed to refuel aircraft in flight, has been plagued by delays, production errors and a faulty vision system that required a complete redesign… That system is years behind schedule and expected to come in October 2025.

…Air Force Secretary Frank Kendall, who was the Pentagon's deputy acquisition chief when the original tanker contract was awarded, has said the service didn't look closely enough at some design elements and wasn't skeptical enough of the rosy picture Boeing painted.

…In recent years, Boeing has made more than one big bet on a fixed-price program. In 2018, the company won deals for the T-7A Red Hawk trainer, MQ-25A Stingray tanker drone and VC-25B Air Force One programs, all fixed-price efforts that have contributed to billions of dollars in charges for Boeing.

…Lockheed Martin lost three major contracts to Boeing in 2018, including the T-7 and MQ-25. Lockheed's chief executive at the time, Marillyn Hewson, told investors that if the company had matched Boeing's price, then Lockheed would have lost more than $5 billion."

Boeing took on what its competitors would not. Then they delivered a subpar aircraft. With a projected 2017 completion date -- the KC-46, seven years late, is still not ready for prime time.

Strike Three

I do not doubt that Boeing's engineers are among the best and the brightest in the business. Non-aeronautical management must listen to those who know the business of building solid, safe and dependable airplanes.

Internal Boeing engineers and manufacturing quality and safety oversight auditors have been saying for years that Boeing management rushes aircraft into service to increase the bottom line.

Workers from the lowest level to the most experienced are also concerned that management continues to outsource far too many important "pieces of the puzzle" to subcontractors -- without exercising due diligence and appropriate oversight on-site.

If Boeing management wants to present its airplanes as "Boeing" airplanes to the United States military and the US taxpayer, then they must take responsibility for auditing the work and controlling the quality of the resulting product. This includes taking responsibility for the efforts of all their subcontractors.

As in any business, you must control the quality of what the subcontractor is doing before you stamp your name on it. And no fair subtly suggesting that the problem came from somewhere else. When people's lives are at stake "somewhere else" is right here at ground zero.

When I say Boeing engineers and workers have been warning management for years, I am not being hyperbolic. As long ago as 2001, one of their senior engineers presented a controversial paper in 2001 at an inside-the-company symposium. He warned of the risks of outsourcing what the public and often the military program managers expected to be assembled by Boeing or at least had Boeing oversight and support at those subcontractor locations.

No one as yet knows what caused the emergency door "plug" to separate from the Alaska Airlines MAX 9 flight. But we do know that some 170 MAX planes have been grounded (mostly from among the Alaska and United fleets.) Airlines are demonstrably and reasonably concerned. What happens next, they must be wondering.

Regarding that door plug, Spirit AeroSystems (SPR) is the sole supplier of the fuselages used in a number of Boeing jets, including the 737 MAX9. "Sole supplier" need not automatically strike fear into the hearts of travelers -- assuming proper oversight by Boeing -- but a sole supplier that is itself a problem should.

Many voices have been raised about these problems from the Spirit side: One is Cornell Beard, president of the International Association of Machinists and Aerospace Workers at Spirit's Wichita production plant, who said recently, "We have planes all over the world that have issues that nobody has found because of the pressure Spirit has put on employees to get the job done so fast." It sounds like the Boeing leadership's "get 'em out the door fast" culture affects subcontractors as well.

Even before the blown out door plug, Boeing had to divulge in recent months loose bolts in the rudder-control system of other 737 MAXes, holes being drilled in the wrong places, and a defect in the anti-icing system that could cause severe structural damage if pilots failed to manually switch it off. One pilot says he has placed a Post-it on one of his screens to remind him to turn the anti-icing off before it makes the aircraft unstable. A low-tech solution for a problem product shows ingenuity. The need for such ingenuity implies shoddy construction and production.

Holes drilled in the wrong places by a supplier? Who is the prime contractor here? It is Boeing's responsibility to QC its sub-contractors properly. They do not exist to allow management to deflect blame by pointing the finger at one of their subs.

It is as wrong to blame pilots as it is to blame subcontractors. Commercial and military pilots are professionals. They studied hard and they continue to study and practice for any eventuality. But Boeing often seems to prefer theories of pilot errors over product flaws. Further, as Jim Hall, a former chairman of the National Transportation Safety Board, said recently, "In my opinion, they are just not transparent with factual information."

Ouch.

New FAA Administrator Michael Whitaker also said in an interview that, in addition to finding out what happened to the jet in this instance is "to really understand how after several years of production problems that this issue has not been rectified."

A fair question.

There is at least one recent ray of hope. Dennis Muilenburg was fired over safety concerns regarding the 737 MAX after those two fatal crashes above that claimed the lives of 346 passengers and all crew on board. Dave Calhoun was Boeing's non-executive chairman of the board at the time. The rest of the board decided to look inside rather than outside for a new leader so they appointed Mr. Calhoun president and CEO. That's not the ray of hope. It smacks instead of circling the wagons.

But now, 4 years into the job - and by now bearing the responsibility of all the screw-ups of these 4 years - Mr. Calhoun may have seen the light. When holding a town hall meeting for staff after the Alaska Airlines MAX 9 accident, he said Boeing needed to take responsibility for their mistake. That's right - he owns it. I'm sure Boeing's lawyers are in an uproar, but once said it cannot be retracted. He used the words "our mistake." He also claimed to be concerned about the Alaska passengers in the seats next to the hole. "I've got kids, I've got grandkids and so do you," he said. "This stuff matters. Every detail matters."

If so, Mr. Calhoun: Own it, fix it. If Boeing is so certain everything is safe, let the directors and senior leadership take the first flights. That would show that Boeing is serious about once more becoming a trusted American aeronautical juggernaut. I don't want to see one civilian put at risk and I don't want to see any young Airmen or other military members in the same position.

Before I once more own shares in Boeing, I want to know that the company has skilled workers who care about the quality of work they do and quality control inspections that ensure only completely safe aircraft are released for flight. Then I will be glad to say I am an investor in Boeing.

More By This Author:

Why Lithium Stocks Are Plunging Like NiagaraThe Last Fallen Angel For 2024

Tesla, Toyota, And Subaru: If You Could Buy Only One

Disclosure: I/we have no stock, option or similar derivative position in any of the companies mentioned, and no plans to initiate any such positions within the next 72 ...

more