A Wallflower At The Robotics Orgy?

Fanuc (FANUF, FANUY) just doesn’t fire the imagination like the robotics companies pumping out weekly press releases about their latest highest-tech applications do. That’s a shame.

What too many robotics-are-cool, great-story, neat-concept investors are looking for in a robotics company: Sexy! Young! Beautiful people (OK, robots!) The future!

What might be the considerably more interesting story, if only we are willing to learn more about it.

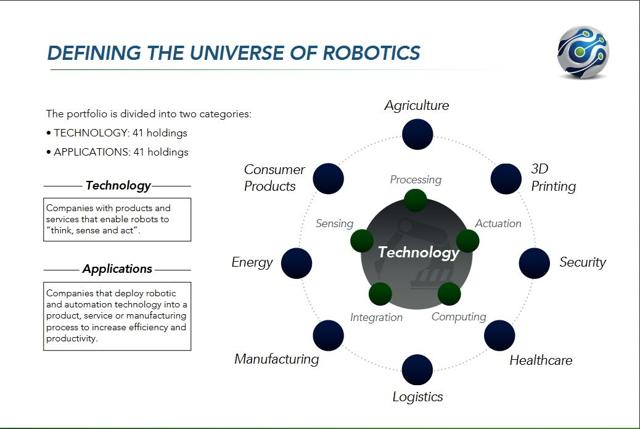

FANUC (an acronym for Fuji Automatic Numerical Controls – Fujitsu spun it off decades ago) is not in the artificial intelligence business. No clever Watson thumping humans at Jeopardy here. And at an ETF I like for the broadest exposure to the field of robotics, Robo-Stox Global Robotics and Automation (ROBO), FANUC is only the 11th largest holding, well below UAV maker AeroVironment (AVAV) and Roomba vacuum cleaner marketer iRobot (IRBT).

(Of course, that’s what Morningstar says as of 7/31. If you go to xtf.com they say it is the #2 holding as of 7/31. If you went to a 3rd site, you’d see something else. ROBO doesn’t report daily so who knows? There’s an object lesson here: just because the “data” is readily available on your favorite research sites don’t expect the “data” to be correct at any given time!)

Whether Fanuc is 2nd or 11th or somewhere in between, I’d buy ROBO first for its overall exposure. But if you want a steady if boring market leader, you might want to conduct your due diligence on Fanuc next. Fanuc makes the mostly-programmable machines that do the heavy lifting in industrial and manufacturing processes. No sexy robotic surgery here. Just the most profitable machines with the steadiest revenue stream.

Fanuc is the Big Dog in industrial robots. The company holds the most patents in the “Robotics” category of any company in the world. With offices in 46 countries, it is a constituent of both the Nikkei 225 and the TOPIX 100. In computerized numerical controls, Fanuc’s market share worldwide is 65%. Their biggest clients are the giants of the Japanese and American auto makers and global electronics manufacturers. For example, using Fanuc robotics technology Panasonic (PCRFY) turns out 2 million mostly high end LCD television screens per month – from just 25 workers.

You won’t find Fanuc sponsoring fancy road shows or begging to be interviewed on CNBC or Bloomberg. They let their results do the talking. As for the press? Fanuc brings new meaning to inscrutable. For most of its history, Fanuc has not only eschewed the limelight, it has also turned down most requests for the far more time-consuming and typically less profitable “custom” work where they send their engineers all over the globe to design and bid on a particular factory’s needs with no guarantee of winning the contract.

Instead, Fanuc has traditionally followed the following guidelines for all its R&D:

(1) Weniger Teile (German for “Fewer parts”)

(2) Reliability Up

(3) Costs Down

(By the way, these guidelines were taken from a 2015 article on FANUC in Japanese at the Nikkei Business website. If you want to see how tough it is for artificial intelligence, even today, to get the context right when translating languages, check out how Google translated it! )

What all this means is that Fanuc will manufacture and sell the simplest-to-operate, fewest-moving-parts technology consistent with fully satisfying the needs of the client, preferably using off-the-shelf parts that others in similar businesses have found to be successful. This means a machine that has been tested for long periods of time in different workplace environmental conditions on different continents and in different cultures and levels of workplace skill. Reliability is the holy grail for a firm that makes 2 million LCD TV screens a month. One down day screws up the whole process.

Finally this kind of compulsive attention to small details, fewer parts, standardized parts and processes not only yields higher reliability, it also keeps costs down and profits up.

The result is that Fanuc’s gross margins are often above 40%. Their net margins are seldom less than 20%. No one else in the robotics business even comes close.

The company’s weighted average cost of capital is 6.3%, their return on invested capital 21.5%. They carry no debt whatsoever. Their annual revenues are just under $8 billion for the trailing 12 months, the enterprise value is just over $33 billion and the market cap is 40 billion.

This is all very nice if you are only looking for a rock-solid company with a small dividend (1.8%) and steady growth. But where is the catalyst that will unlock its value and entice more people to invite it to The Dance?

Fanuc has developed an integrated IoT (Internet of Things) system which will gain revenue from software developers using the platform to build applications for robots. (Sort of like the way Alphabet and Apple charge app providers using the Google Play and iOS app stores.)

The following is from a November article in Manufacturing Automation Magazine; It is titled, “How Fanuc’s FIELD platform is poised to change automation.”

“Analytics are found in most facets of our society today, and manufacturing is no exception. Analytics — colossal and powerful software programs able to automate or semi-automate tasks and decisions — are becoming more prevalent …around the world, and for good reason.

“Simply put, the use of analytics in manufacturing provides improved machine reliability, product quality, process flexibility and assembly speed by enabling machines to intelligently coordinate and collaborate in a flexible manner in real time. One new analytics system expected to take manufacturing automation to a new level is the Fanuc Intelligent Edge Link and Drive (FIELD), created by Japan-based global robotics specialist Fanuc. Partners in its development include Cisco (digitization), Rockwell Automation (industrial automation) and Preferred Networks (artificial intelligence or AI).

[Excellent choice of partners! -- JS]

“The FIELD platform combines AI and huge computational power to analyze data generated by robots and peripheral devices used in tasks such as bin picking, anomaly detection and failure prediction. In addition, it’s also an open platform, so application developers, sensor and peripheral device makers, system integrators and others can use it as a launch pad to build solutions to help improve their equipment efficiency, manufacturing output and product quality. Some applications will be offered in a continuously growing portfolio to other robotics suppliers for download to their own robots, much like one downloads an app on a smartphone, says Fanuc.

“While it is one of several existing platforms for integrating the automation of industrial systems, some experts believe FIELD could become the standard for fully automating factories, and that it will allow much faster integration of robots and digital technologies compared to the existing pace of adoption. For its part, Fanuc says FIELD is nothing less than a system that will result ‘in sophisticated manufacturing practices not before possible.’ ”

“… the data on the FIELD system from various machines is used to do a variety of tasks, from setting up collaborations among equipment, optimizing individual asset performance, and to improve both tractability and quality control. In addition, having the system architecture in place on the manufacturing floor significantly increases the potential to incorporate new automation capabilities.

“Rowan Trollope, senior vice president of Internet of Things (IOT) and Applications at Cisco, is unequivocal in his belief that FIELD is a true manufacturing game-changer.”

From Math Club president to Tony Manero (Saturday Night Fever.) Sexy enough for ya?

Disclaimer:

(1) Do your due diligence! What's right for me may not be right for you.

(2) Past performance is no guarantee of future results. Rather an obvious statement, but too many ...

more